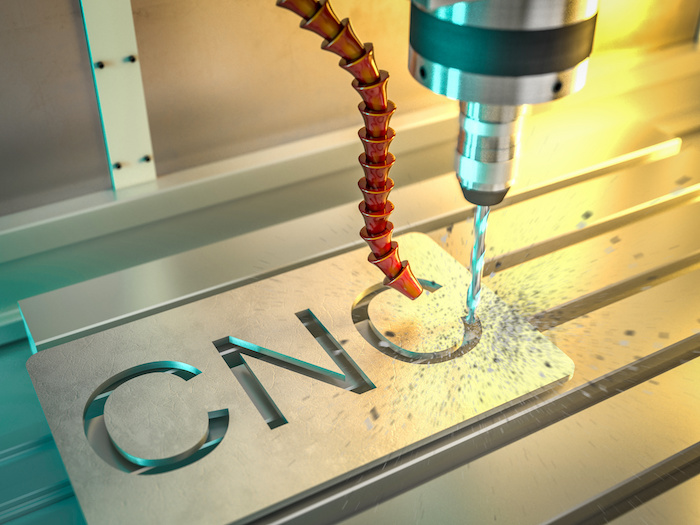

CNC (Computer Numerical Control) routers have revolutionized metalworking, enabling precise and efficient cutting, carving, and shaping of aluminum. Choosing the best CNC router for aluminum requires understanding key factors such as spindle power, cutting speed, and rigidity. In this article, we will explore everything you need to know about CNC routers for aluminum and help you select the best machine for your needs.

Why Use a CNC Router for Aluminum?

Aluminum is a widely used material in industries such as aerospace, automotive, and manufacturing due to its lightweight and durability. However, machining aluminum can be challenging due to its tendency to generate heat and clog cutting tools. A CNC router for aluminum is designed to handle these challenges efficiently, offering precision, consistency, and high-speed performance.

Advantages of Using a CNC Router for Aluminum

- Precision and Accuracy – CNC routers offer unparalleled accuracy, ensuring high-quality cuts and intricate designs.

- Increased Efficiency – Automated cutting reduces manual labor and speeds up production.

- Versatility – These machines can handle different types of aluminum, from thin sheets to thick blocks.

- Cost-Effectiveness – Reduces material wastage and improves productivity, lowering overall manufacturing costs.

- Ease of Use – Advanced software integration allows for user-friendly operation, even for beginners.

Key Factors to Consider When Choosing the Best CNC Router for Aluminum

Selecting the right CNC router for aluminum requires evaluating specific features that impact performance. Here are the essential factors to consider:

1. Spindle Power and Speed

The spindle is the heart of any CNC router. When cutting aluminum, a high-powered spindle (at least 1.5 kW or higher) is essential to handle the material efficiently. Variable speed control allows for optimized cutting speeds, reducing the risk of overheating.

2. Rigidity and Build Quality

Aluminum cutting requires a sturdy and vibration-resistant frame. Look for routers made from cast iron or heavy-duty aluminum to ensure stability. A rigid structure minimizes deflection, improving accuracy and surface finish.

3. Cutting Bed and Work Area

The size of the cutting bed determines the dimensions of aluminum sheets you can process. Choose a work area that matches your project requirements. T-slot beds are preferred for aluminum as they provide better material hold-down.

4. Cooling and Chip Management

Aluminum generates heat during cutting, so an effective cooling system (mist or air cooling) is essential. Additionally, a good chip evacuation system prevents material buildup, improving efficiency and prolonging tool life.

5. Software Compatibility

Ensure that the CNC router is compatible with leading CAD/CAM software such as Fusion 360, VCarve Pro, or AutoCAD. These programs help in designing complex patterns and controlling machine movements precisely.

Top Picks: Best CNC Routers for Aluminum

Here are some of the top CNC routers for aluminum, based on performance, durability, and customer feedback.

1. BobsCNC Evolution 4

- Spindle Power: Compatible with powerful routers

- Work Area: 24″ x 24″ x 3″

- Frame Material: Plywood

- Best For: Hobbyists and small-scale aluminum projects

This router is an affordable option for beginners. While not as rigid as metal-framed routers, it can handle aluminum with proper speed adjustments.

2. Shapeoko 4 XXL

- Spindle Power: Upgradeable

- Work Area: 33″ x 33″ x 4″

- Frame Material: Aluminum and steel

- Best For: Small businesses and makers

The Shapeoko 4 XXL offers a sturdy frame and excellent precision, making it a great choice for cutting aluminum efficiently.

3. Avid CNC PRO4896

- Spindle Power: 3 kW and above (customizable)

- Work Area: 48″ x 96″

- Frame Material: Steel

- Best For: Professional workshops and industrial applications

With its industrial-grade construction and high-power spindle, this CNC router is ideal for heavy-duty aluminum machining.

4. Tormach 24R Router

- Spindle Power: 2.2 kW

- Work Area: 24″ x 24″

- Frame Material: Steel and aluminum

- Best For: Precision aluminum machining

This router is specifically designed for metal cutting and offers excellent rigidity and cooling options.

Tips for Machining Aluminum with a CNC Router

Using a CNC router for aluminum effectively requires specific techniques to enhance performance and tool longevity.

- Use the Right Cutting Tools – Carbide end mills are ideal for aluminum as they offer better durability and heat resistance.

- Optimize Feed and Speed – Too fast can cause overheating; too slow can lead to tool wear. Follow manufacturer recommendations for best results.

- Use Proper Lubrication – Mist or air cooling systems prevent overheating and improve surface finish.

- Secure the Material – A vacuum or T-slot bed helps in holding the aluminum sheet firmly in place.

- Clear Chips Regularly – A dust collection system prevents clogging and enhances cutting efficiency.

Final Thoughts

Choosing the best CNC router for aluminum depends on your project needs, budget, and desired precision. Whether you’re a hobbyist, small business owner, or industrial manufacturer, investing in the right CNC router can significantly improve your workflow and product quality.

By considering factors such as spindle power, rigidity, work area, and cooling systems, you can select a machine that meets your aluminum machining needs efficiently. With the right router and machining techniques, working with aluminum can be smooth, precise, and highly productive.